Products

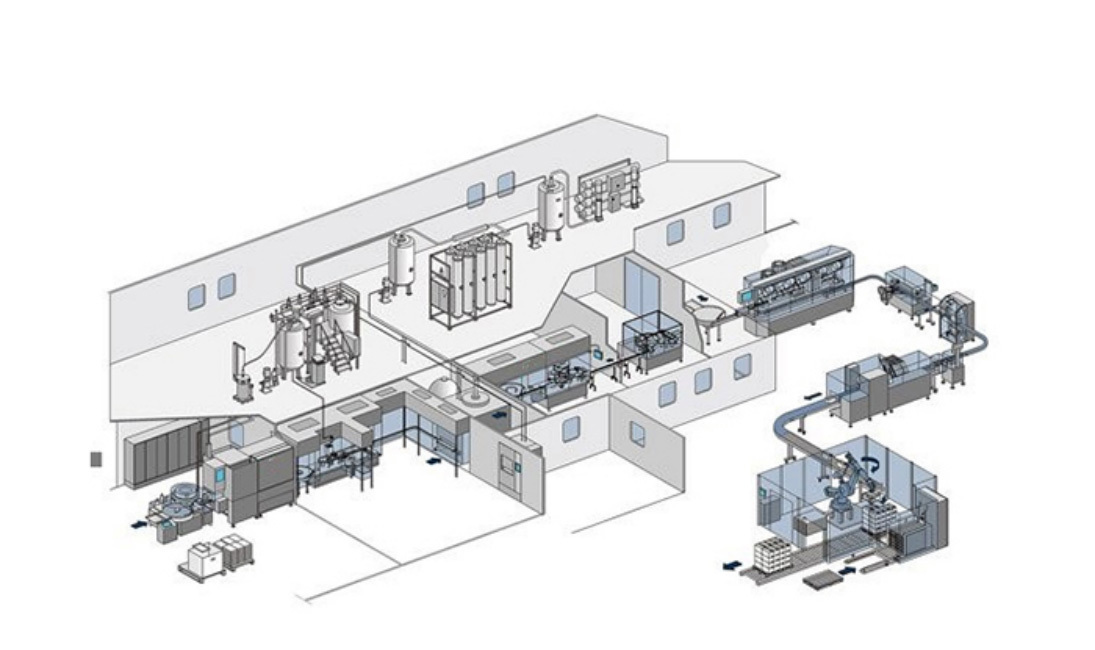

Liquid Distribution Module System

- Working Principle

- Core Features

- Technical Parameters

- Application Industry

-

Buffering regulation: Provide sufficient storage space for PW and WFI to buffer the supply and demand difference between water production and water use, and ensure stable water supply. For example, when the production capacity of water production equipment is greater than the water demand in a certain period of time, the excess water can be stored.

Water quality maintenance: Equip with corresponding measures to maintain the water quality of stored water, such as using nitrogen protection and other methods to isolate the air, reduce the impact of dissolved oxygen in water on water quality, and prevent substances in water from being oxidized.

Safe transportation: Use high-quality pipeline materials and reasonable pipeline layout to safely transport PW and WFI to various water use points to ensure that the water quality is not polluted during the transportation process.

Parameter control: Accurately control parameters such as pressure, flow and temperature during the transportation process to meet the needs of different water use points. For example, for some processes that have strict temperature requirements, the distribution module can control the water temperature through equipment such as heat exchangers.

-

1. PW/WFI modular design, compact structure, easy operation and maintenance;

2. Support customized multi-circuit circulation, variable frequency operation of circulating pump, system process design and operation meet the requirements of GMP and ISPE guidelines;

3. Fully automatic control of online cleaning and disinfection of storage and distribution system;

4. Design and build overall solutions such as purified water, injection water, pure steam, compressed air, nitrogen, etc. that meet the process requirements of pharmaceutical companies;

5. The control system can automatically generate electronic reports and electronic records, and has audit tracking, intelligent maintenance, and remote troubleshooting functions.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Are you manufacturer or trader? Where are your factory located?

We are manufacturer. Our factory is located in Changsha and Suzhou.

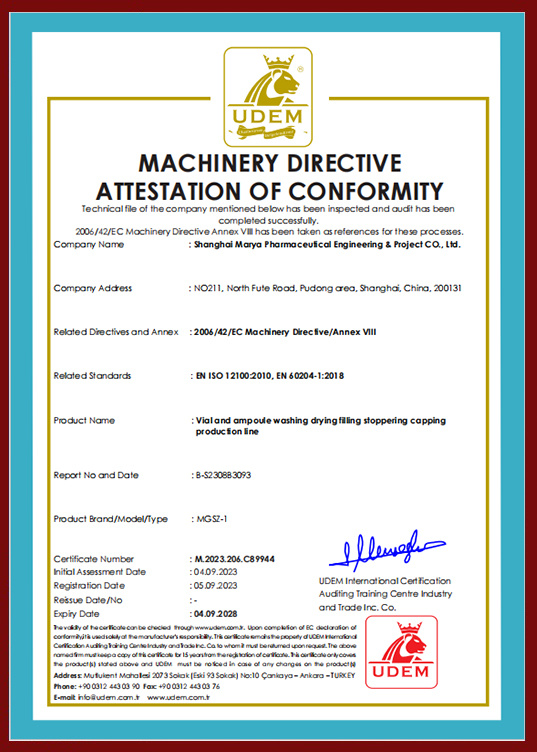

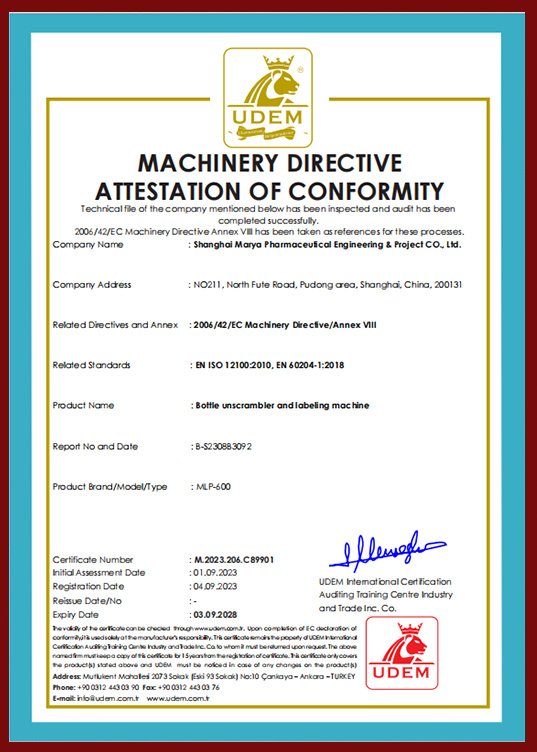

What certificate do you have?

We have CE, ISO, ROHS, SGS etc.

What documents will you provide?

Usually we will provide DQ, IQ, PQ, OQ, FAT, SAT, operation manual, maintenance instruction,layout drawing.etc.

What is the production lead time?

Standard 25-60 days after deposit received and technical data confirmed, we can make special arrangement for better shipment if needed;

Standard 60-150 days after deposit received and technical data confirmed based on different machines, we can make special arrangement for better shipment if needed.

How long is your warranty? Can we extend?

12 months after installation and commissioning or 18 moths from the day that the equipment arrived on site. Prevail in the first arrival date.

Warranty can be extended with extra charge.

Have you done similar projects overseas?

Marya’s business map covers more than 60 countries and regions around the world, such as the United States, Russia, Bulgaria, Britain, Portugal, Poland, Switzerland, ltaly, New Zealand, Malta, Moldova, Malaysia, Uzbekistan, lran, Egypt, Saudi Arabia, UAE, Ecuador, Dominica, Panama, Uruguay, Argentina, Tanzania, Zimbabwe, Ethiopia, Indonesia, Bangladesh, and others, and we gained good reputation.

Key words:

Liquid Distribution Module System

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Sterile Water Treatment Solution

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131