Products

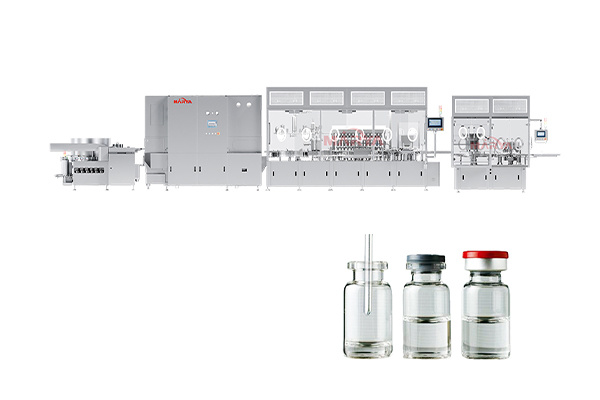

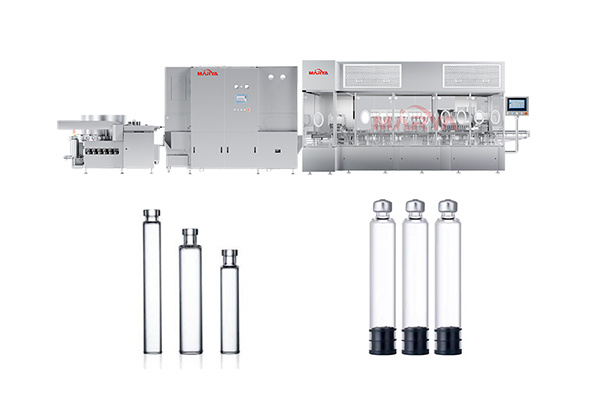

Cartridge Filling Machine

- Core Advantages

- Core Technology

- Technical Parameters

- Application Scenarios

- Optional Systems

-

High-precision filling: Adopting advanced metering system to ensure filling accuracy within ±0.5% deviation;

Aseptic guarantee: Equipped with Open-RABS or isolator system;

Efficient production: Fully automated with high-speed filling, reaching up to 400 bottles per minute, significantly improving efficiency;

High flexibility: Adaptable to different sizes of cartridge bottle specifications with quick changeover, reducing downtime;

High regulatory compliance: Made of 316L stainless steel, conforming to GMP standards, easy to clean and maintain, ensuring product hygiene and safety;

High stability: Equipped with advanced sensor and control system to ensure stable equipment operation and reduce failure rate;

Intelligent control:

· Adopting high precision color touch screen operation and monitoring, PLC automatic control, automatic protection, host frequency conversion speed regulation and other control technologies for fully automatic control and monitoring of the production process;

· This machine is a full servo motor system control model, and the parameters that need to be adjusted can be modified on the touch screen;

· Adopting advanced electric control system, with stepless speed adjustment and comprehensive interlocking functions; all operational parameters are displayed centrally;

· Temperature record and curve graph automatically record and print;

· It has full-line linkage function, enabling linkage control of front and rear equipment. -

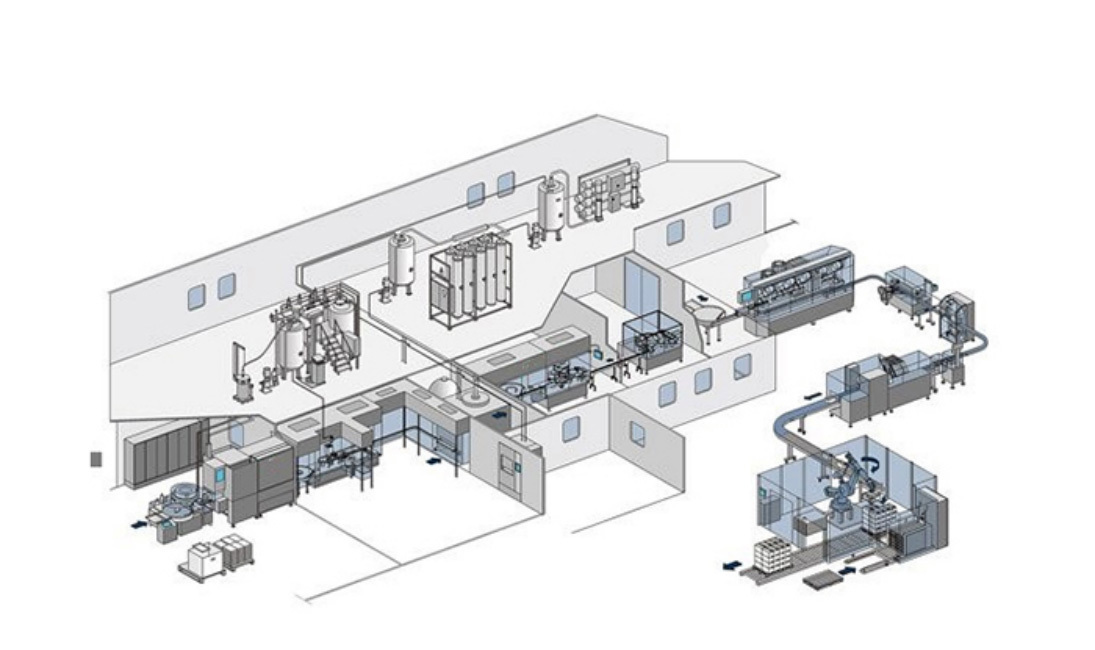

Cleaning process: Utilizes ultrasonic cleaning and sterilization to remove impurities, dust and microorganisms in the bottles to ensure the cleanliness of cartridge bottles and meet the production requirements of pharmaceutical filling;

Sterilization oven: The sterilization oven is suitable for drying and sterilizing ampoules, vials, cartridge bottles, as well as other medicinal glass bottles; the heat source of the tunnel-type hot air circulation oven is evenly distributed, and the pyrogen removal effect is good;

Bottle conveying: The automatic conveying system sends the cartridge bottles into the filling station in an orderly manner;

Precise filling: Liquid or semi-liquid products are injected into bottles through high-precision pump or gravity filling system;

Stoppering and sealing: The servo motor-driven stoppering process ensures high stability and success rates;

Quality Inspection: Equipped with visual inspection system to monitor filling volume and sealing quality in real time, automatically rejecting unqualified products;

Packing and discharge: After finishing filling and sealing, the products automatically enter the packing line for final preparation.The cartridge bottle filling line, with its high efficiency, precision, and flexibility, has become an indispensable equipment in modern production, empowering enterprises to enhance product quality and boost market competitiveness.

-

Wide applicable specifications, large capacity and high filling accuracy

Applicable Specifications 1ml-5ml Production Capacity ~12000 bottles/hour Number of Stoppering Heads 10 Number of Filling Heads 20 (divided into two fillings) Filling Accuracy ±5%(according to drug characteristics and filling volume) Pass Rate of Plugging ≥99% Capping Qualification Rate ≥99% Power Requirement 220V/380V, 50/60Hz Air Source Requirement 0.6-0.8 MPa -

Pharmaceutical industry: Used for filling vaccines, insulin, antibiotics, interferon, anesthesia sedatives and other drugs.

Medical industry: Finished products are used in ophthalmology, stomatology, otology, orthopedics, gynecology and so on.

Cosmetic industry: For the filling of serum, hyaluronic acid/collagen, hydrodermic injections/microneedle solutions and other products. -

Automatic bottle loading system: to realize automatic bottle feeding, reduce manual operation.

Labeling system: to provide automatic labeling to improve packaging efficiency.

Regulatory code system: to print QR code on the packaging of different levels of products, with identification and correlation between the QR code, which facilitates the traceability and management of the quality of product batches.

Audit tracing system: contains product batch records, operation logs, electronic signature traceability, etc. It meets the requirements of FDA 21CFR part 11 for software systems.

Configurable systems:

· Online cleaning and sterilization CIP/SIP system;

· Online sterilization function for the cooling section of tunnel-type hot air circulation oven;

· Vacuum filling system for filling high viscosity products;

· Fully enclosed sterile isolator system can be equipped according to whether the customer’s products are toxic or active.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Are you manufacturer or trader? Where are your factory located?

We are manufacturer. Our factory is located in Changsha and Suzhou.

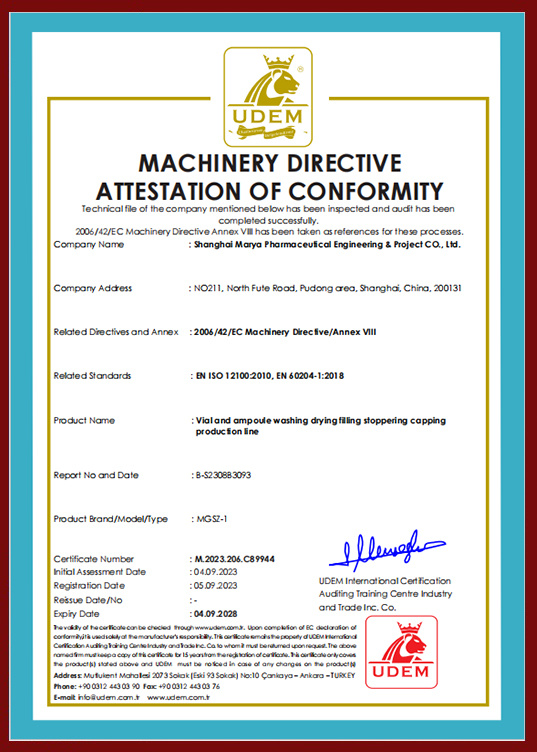

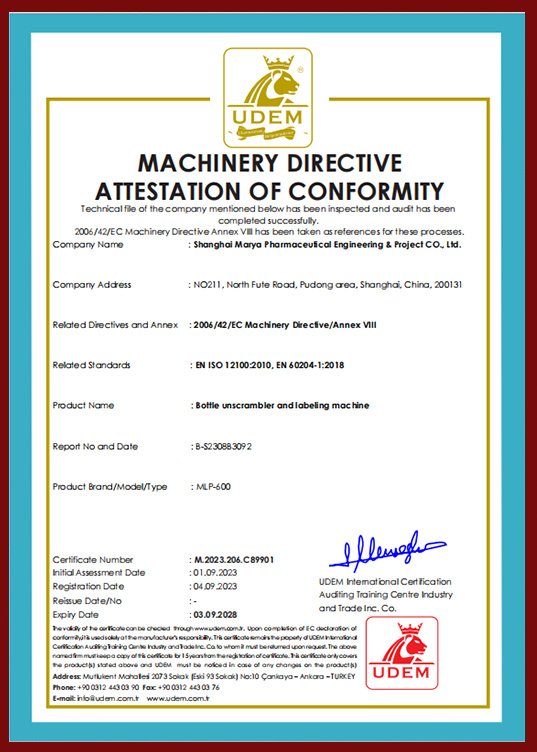

What certificate do you have?

We have CE, ISO, ROHS, SGS etc.

What documents will you provide?

Usually we will provide DQ, IQ, PQ, OQ, FAT, SAT, operation manual, maintenance instruction,layout drawing.etc.

What is the production lead time?

Standard 25-60 days after deposit received and technical data confirmed, we can make special arrangement for better shipment if needed;

Standard 60-150 days after deposit received and technical data confirmed based on different machines, we can make special arrangement for better shipment if needed.

How long is your warranty? Can we extend?

12 months after installation and commissioning or 18 moths from the day that the equipment arrived on site. Prevail in the first arrival date.

Warranty can be extended with extra charge.

Have you done similar projects overseas?

Marya’s business map covers more than 60 countries and regions around the world, such as the United States, Russia, Bulgaria, Britain, Portugal, Poland, Switzerland, ltaly, New Zealand, Malta, Moldova, Malaysia, Uzbekistan, lran, Egypt, Saudi Arabia, UAE, Ecuador, Dominica, Panama, Uruguay, Argentina, Tanzania, Zimbabwe, Ethiopia, Indonesia, Bangladesh, and others, and we gained good reputation.

Key words:

Cartridge Filling Line

Cartridge Filling Capping Line

Cartridge Bottle Filling Line

Cartridge Filling Machine

Pharmaceutical Cartridge Filling Machine

Cartridge Filling Machine Manufacturer

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131