Products

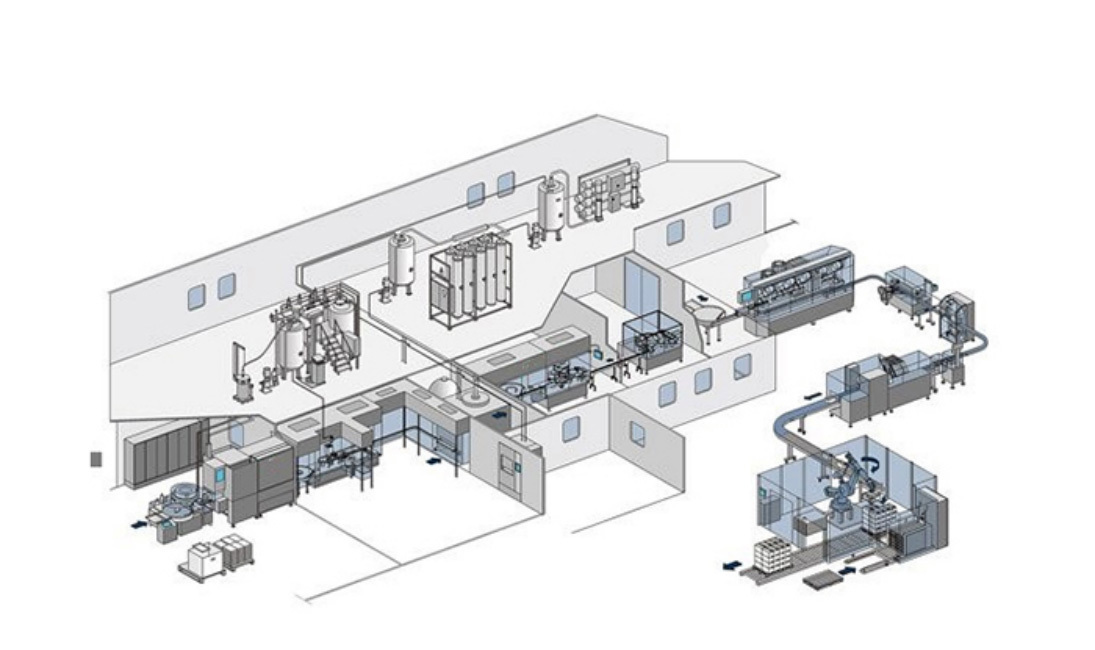

Pre-Filled Syringe Filling Line

- Core Advantages

- Core Technology

- Technical Parameters

- Application Scenarios

- Optional Systems

-

High-Precision Filling: Adopting advanced servo-driven system and precision metering pumps to ensure that the filling volume of each syringe is highly accurate, and the error can be controlled within ±0.5% at the highest.

High-Efficiency Production: High degree of automated operation with filling speed exceeding 400 pcs per minute, improving production efficiency.Aseptic Environment: Fully enclosed design with aseptic isolator system and high efficiency articulate air (HEPA) to ensure that the filling process is carried out in Class A sterile condition, preventing cross-contamination.

High Flexibility: It can be adapted to a variety of specifications of pre-filled syringes and supports quick changeover capability to reduce downtime.

Increased Productivity: High-speed operation can process up to 24,000 syringes per hour (depending on model).

Regulatory Compliance: The design meets GMP, FDA and ISO sterile standards for sterile drug manufacturing.

Intelligent Control System:

Adopting high-precision color touch screen operation and monitoring, PLC control system and industrial control machine to realize the whole automated operation, main unit variable frequency speed regulation and real-time monitoring, supporting data tracing and recording.

This syringe liquid filling machine adopts servo control system to automatically complete the process of honeycomb tray unpacking, film tearing, conveying, filling, plug filling and tray output, etc. It’s with electromechanical integration control, stable operation and high degree of automation. -

Syringe Feeding & Positioning: The automatic feeding system precisely positions the syringe to ensure the stability of the filling process.

Pharmaceutical Liquid Filling: Servo-controlled filling system guarantees precise dosage accuracy, minimizes product loss, and achieves bubble-free filling. Supports liquid, viscous solutions, and suspension formulations.

Stoppering & Sealing: High-precision automatic rubber stopper insertion maintains the sealing and sterility of the syringe.

Visual Inspection: Optional syringe light inspection machine, integrated camera system to automatically detect foreign matters, air bubbles and abnormal filling volume in the syringe.

Packaging & Palletizing: Smart packaging line automates cartoning, labeling, and palletizing, reducing manual intervention.

-

Filling Volume 1ml-20ml(can be customized according to syringe type) Filling Accuracy ±5%(according to drug characteristics and filling volume) Filling Heads 2-10, to be selected according to the output Production Capacity Up to 24,000 units/hour (varies by model and configuration) Filling Pumps Metal pump, peristaltic pump, ceramic pump Qualified Rate ≥99.9% Syringe Compatibility Glass and plastic syringes (RTU nest box packaging) Material Compatibility Liquid, viscous and suspension formulations Power Supply 380V, 50/60 Hz (can be customized according to regional requirements) Compliance GMP、FDA、ISO 13485 -

Vaccine production: for large-scale filling needs such as COVID-19 vaccines and influenza vaccines.

Biological preparation: for filling of monoclonal antibodies, cell therapy drugs and other high-value biological preparations.

Insulin injection: to meet the precise filling requirements of diabetes treatment drugs.

Beauty and medical aesthetics: for filling of hyaluronic acid, botulinum toxin and other medical aesthetic products. -

▸ Sterility Enhancement System

Isolator + BIBO System: to improve aseptic level of filling environment for highly sensitive drugs.

Automatic Cleaning and Sterilization System (CIP/SIP): to realize automated on-line cleaning and sterilization and reducing downtime.

Nitrogen Filling Unit: to isolate the drug solution from oxygen.

▸ Intelligent Inspection System

Weighing Feedback System: to calibrate the filling volume by real-time weighing, ensuring higher accuracy.

Configurable vacuum filling system for high-viscosity products.

Configurable high performance no bottle no filling, no bottle no capping and linked bottle squeeze stop function.

▸ Automation System

Optional twisted rod labeling machine: automatically insert the plunger rod into the syringe, and complete the syringe labeling, getting ready for final use;

Optional auto-calibration function to realize fully automated filling volume adjustment.▸ Data Management System

Robot palletizing system: automatically completes the palletizing of finished boxes to improve packaging efficiency.

Audit tracking system: configured with Siemens industrial control machine and WinCC system to realize full recording and tracing of production data.

Laser coding system: print batch number, expiration date and other information on the syringe for easy traceability.Tailored solutions available for specialized production requirements.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Are you manufacturer or trader? Where are your factory located?

We are manufacturer. Our factory is located in Changsha and Suzhou.

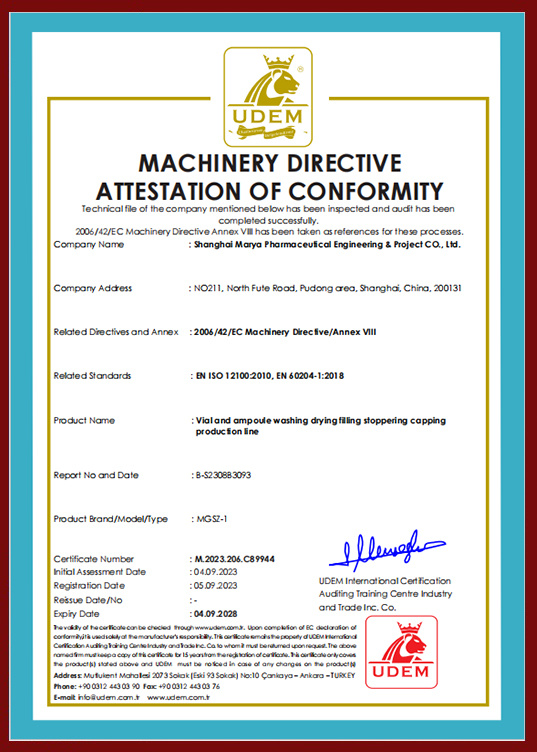

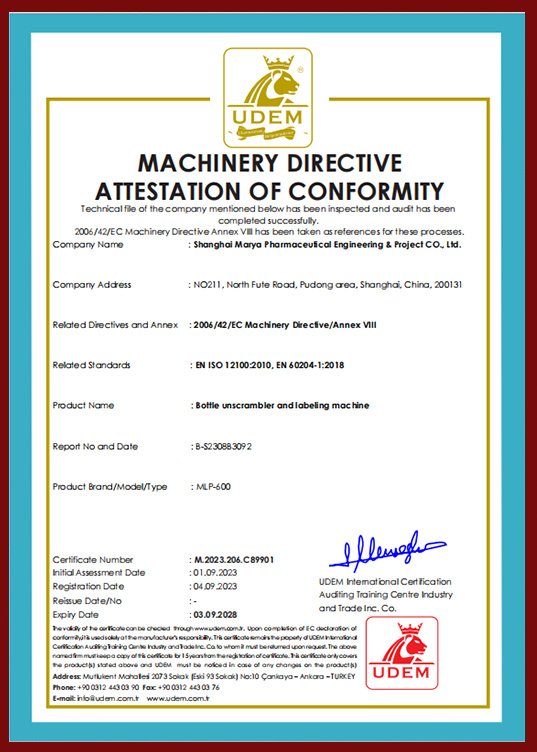

What certificate do you have?

We have CE, ISO, ROHS, SGS etc.

What documents will you provide?

Usually we will provide DQ, IQ, PQ, OQ, FAT, SAT, operation manual, maintenance instruction,layout drawing.etc.

What is the production lead time?

Standard 25-60 days after deposit received and technical data confirmed, we can make special arrangement for better shipment if needed;

Standard 60-150 days after deposit received and technical data confirmed based on different machines, we can make special arrangement for better shipment if needed.

How long is your warranty? Can we extend?

12 months after installation and commissioning or 18 moths from the day that the equipment arrived on site. Prevail in the first arrival date.

Warranty can be extended with extra charge.

Have you done similar projects overseas?

Marya’s business map covers more than 60 countries and regions around the world, such as the United States, Russia, Bulgaria, Britain, Portugal, Poland, Switzerland, ltaly, New Zealand, Malta, Moldova, Malaysia, Uzbekistan, lran, Egypt, Saudi Arabia, UAE, Ecuador, Dominica, Panama, Uruguay, Argentina, Tanzania, Zimbabwe, Ethiopia, Indonesia, Bangladesh, and others, and we gained good reputation.

Key words:

plastic PFS filling machine

pre-filled syringe filling machine

syringe filling machine

PFS filling machine

syringe filling line

Plastic PFS filling machine

prefilled syringe filling machine

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131