Products

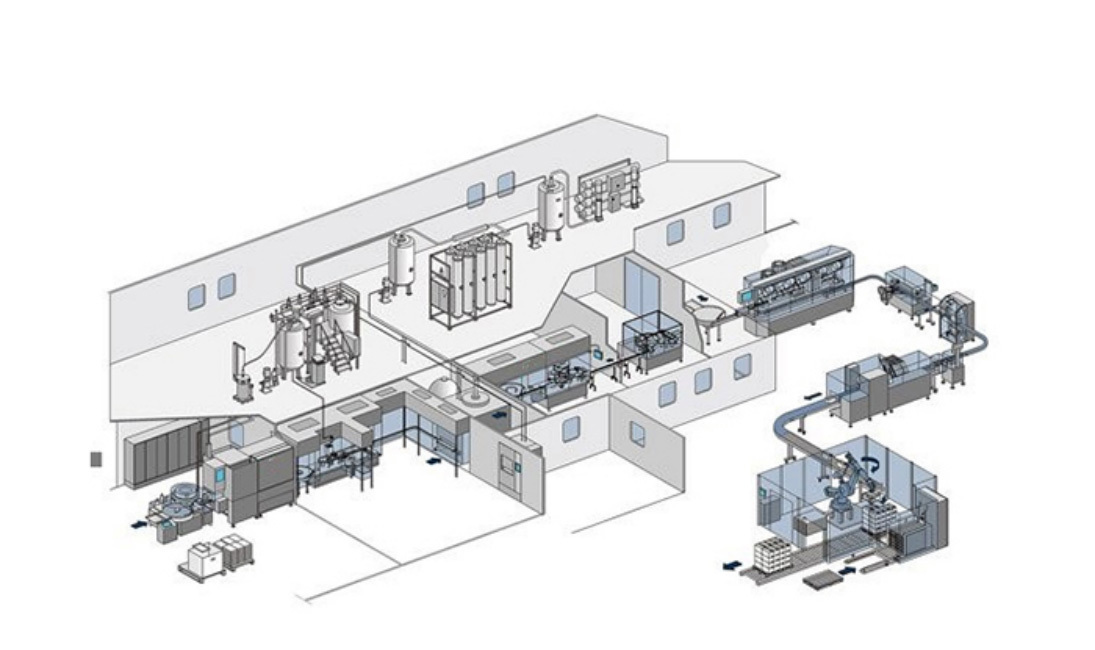

Pharmaceutical Purified Water Generator

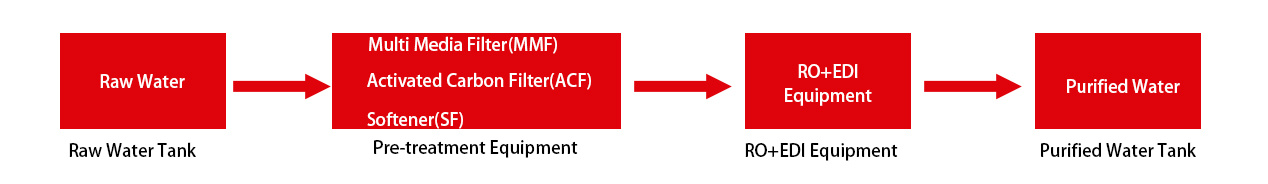

purified water machine is an indispensable piece of equipment for industries that demand high-quality purified water, providing a stable and reliable source of pure water through its advanced purification technologies and excellent performance.

The purified water equipment of MARYA can efficiently produce pharmaceutical-grade purified water that complies with GMP standards, based on membrane technology.

- Working Principle

- Core Features

- Technical Parameters

- Application Industry

-

-

1、Modular design, compact structure, simple and quick on-site installation.

2、Advanced automatic control mode ensures continuous, stable and reliable operation.

3、Double softening in series with alternate regeneration effectively controls microorganisms.

4、Design without an intermediate water tank avoids the risk of secondary pollution.

5、Full pasteurization, flexible disinfection method.

6、Dual water supply and a unique circulation mode prevent the growth of microorganisms throughout the system.

7、Constant pressure control mode prevents the system pressure from being too high during the circulation state, prolonging the service life of EDI.

8、The recovery rate of the reverse osmosis system can be automatically adjusted, or a concentrated water recovery device can be optionally equipped, which greatly saves energy.

9、Flexible water supply reduces downtime, saves energy and improves the service life of the equipment.

10、We can provide Validation documents include DQ, IQ, OQ.

-

Design Pressure(MPa) Max. 4 Mpa Working Pressure(MPa) Max. 4 Mpa(PW production Pressure:0.15~0.25Mpa) Purified water output(L/h) 250L/H~20000L/H Purified water temperature(℃) 20~30℃ PH Value 5.0-7.0 Conductivity (at 25 °C) ≤1.3μs/cm Total Organic Carbon (TOC) ≤250ppb(25℃) Microbial Limit Escherichia coli, Salmonella, and Pseudomonas aeruginosa shall not be detected The total number of bacteria, molds, and yeasts shall not exceed 2 per 100 ml The total number of bacteria, molds, and yeasts shall not exceed 10 per 100 ml -

① Preparation and cleaning of non-sterile pharmaceutical preparations such as oral dosage forms and topical preparations in the pharmaceutical industry.

② Initial rinsing or non-critical cleaning of pharmaceutical equipment, containers, and tools.

③ Routine laboratory testing water.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Are you manufacturer or trader? Where are your factory located?

We are manufacturer. Our factory is located in Changsha and Suzhou.

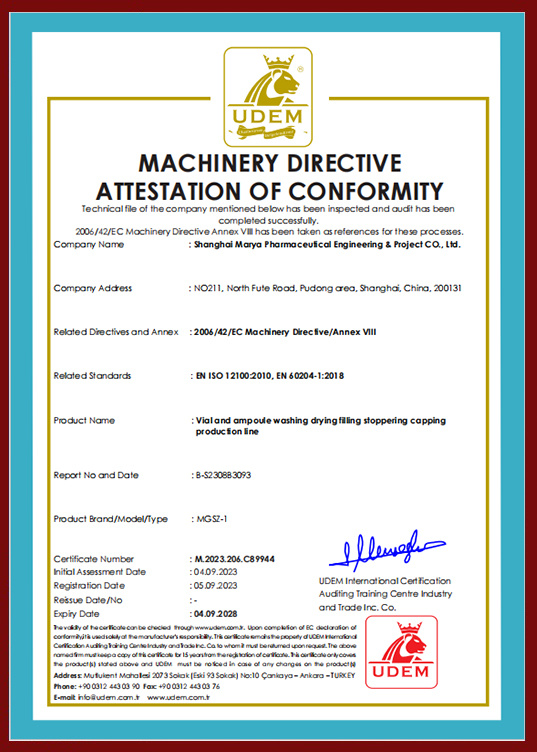

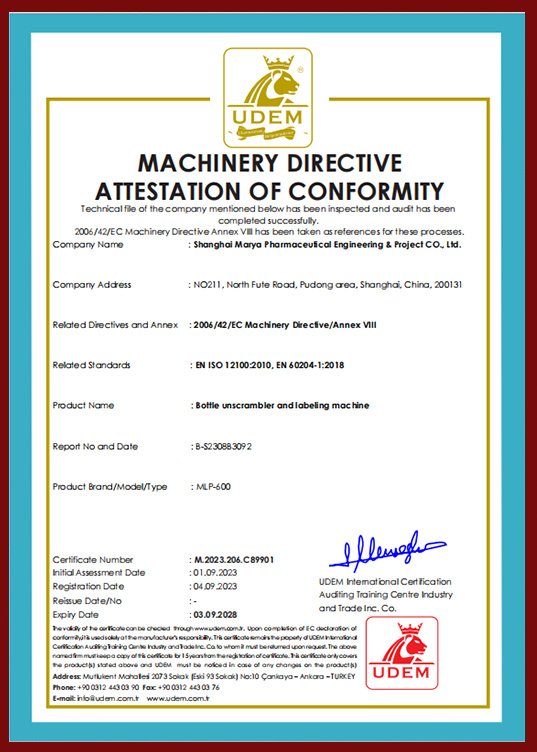

What certificate do you have?

We have CE, ISO, ROHS, SGS etc.

What documents will you provide?

Usually we will provide DQ, IQ, PQ, OQ, FAT, SAT, operation manual, maintenance instruction,layout drawing.etc.

What is the production lead time?

Standard 25-60 days after deposit received and technical data confirmed, we can make special arrangement for better shipment if needed;

Standard 60-150 days after deposit received and technical data confirmed based on different machines, we can make special arrangement for better shipment if needed.

How long is your warranty? Can we extend?

12 months after installation and commissioning or 18 moths from the day that the equipment arrived on site. Prevail in the first arrival date.

Warranty can be extended with extra charge.

Have you done similar projects overseas?

Marya’s business map covers more than 60 countries and regions around the world, such as the United States, Russia, Bulgaria, Britain, Portugal, Poland, Switzerland, ltaly, New Zealand, Malta, Moldova, Malaysia, Uzbekistan, lran, Egypt, Saudi Arabia, UAE, Ecuador, Dominica, Panama, Uruguay, Argentina, Tanzania, Zimbabwe, Ethiopia, Indonesia, Bangladesh, and others, and we gained good reputation.

Key words:

Previous:

Contact MARYA Engineers to Claim Your Free GMP compliant Sterile Water Treatment Solution

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131